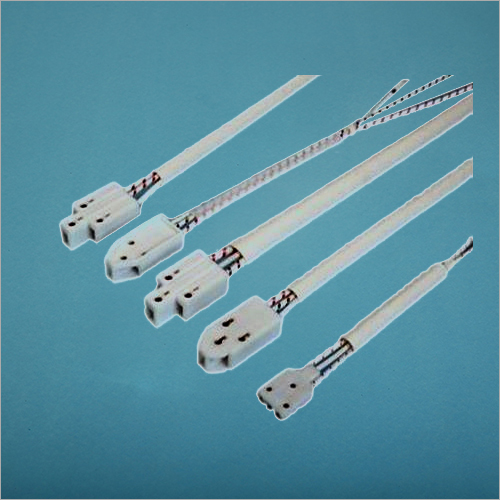

Hermetic Compressors Lead Wire Assembly

Price 12 INR/ Unit

Hermetic Compressors Lead Wire Assembly Specification

- Product Type

- DMD Lead Wires Assembly

- Rated Voltage

- 600 Volt (V)

- Application

- Electronic

- Color

- multicolour

- Molding Material

- Copper

- Warranty

- 1 Year

Hermetic Compressors Lead Wire Assembly Trade Information

- Minimum Order Quantity

- 5000 Units

- Supply Ability

- 10000 Units Per Month

- Delivery Time

- 1 Months

About Hermetic Compressors Lead Wire Assembly

We process the industrial approved DMD Lead Wires Assembly through programmed wire handling machines to create the lead wires required for Hermetic applications. Whole process is automated be it warm stripping, pleating defusing, hitching or last get together testing. We are pleased say that we are a zero imperfection Lead Wires Assembly provider to every one of our clients. Most likely our supply history of most recent 2 decades and experience tally in keeping up the zero ppm levels. These wire assemblies are made with precision and care so the user in the future would not have to worry about the maintenance of the product. We are 100 sure to provide an item that will satisfy.

Product Details

|

Voltage |

600 V |

|

Usage/Application |

COMPRESSORS,HERMETIC SEALED MOTOR |

|

Brand |

HT |

|

Wire Core Material |

Copper |

FAQs of DMD Lead Wires Assembly:

Q: How is the DMD Lead Wires Assembly used in electronic applications?

A: The assembly connects components within electronic devices or systems, ensuring efficient electrical transmission while allowing for easy identification with its multicolour design for streamlined installation.Q: What are the benefits of choosing copper as the molding material?

A: Copper offers excellent electrical conductivity, reduces energy loss, and provides enhanced durability. This ensures a long-lasting and reliable connection in various electronic applications.Q: When can I expect the warranty coverage on the DMD Lead Wires Assembly to begin?

A: The one-year warranty is effective from the date of purchase, covering any manufacturing defects or performance-related issues encountered during regular usage within the warranty period.Q: Where can the DMD Lead Wires Assembly be utilized?

A: These lead wires are suitable for a variety of electronic projects, including industrial devices, domestic appliances, and custom-built electronics, wherever high-voltage reliable connections are needed.Q: What is the process for ordering the DMD Lead Wires Assembly as a manufacturer or exporter?

A: Simply contact us with your requirements regarding voltage, color, and application. We supply customized assemblies and ensure they meet industry standards for exporters, manufacturers, and suppliers.Q: How does the multicoloured design benefit installation and maintenance?

A: Multicolour wires simplify identification during assembly or repair, minimizing errors and improving efficiency for technicians and engineers working with complex electronic circuits.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DMD Lead Wire Assembly Category

DMD Lead Wire Assembly

Price 12.0 INR / Number

Minimum Order Quantity : 1000

Features : Durable

Operating Temperature : 105 Celsius (oC)

Molding Material : PVC

Usage & Applications : Wiring

Send Inquiry

Send Inquiry