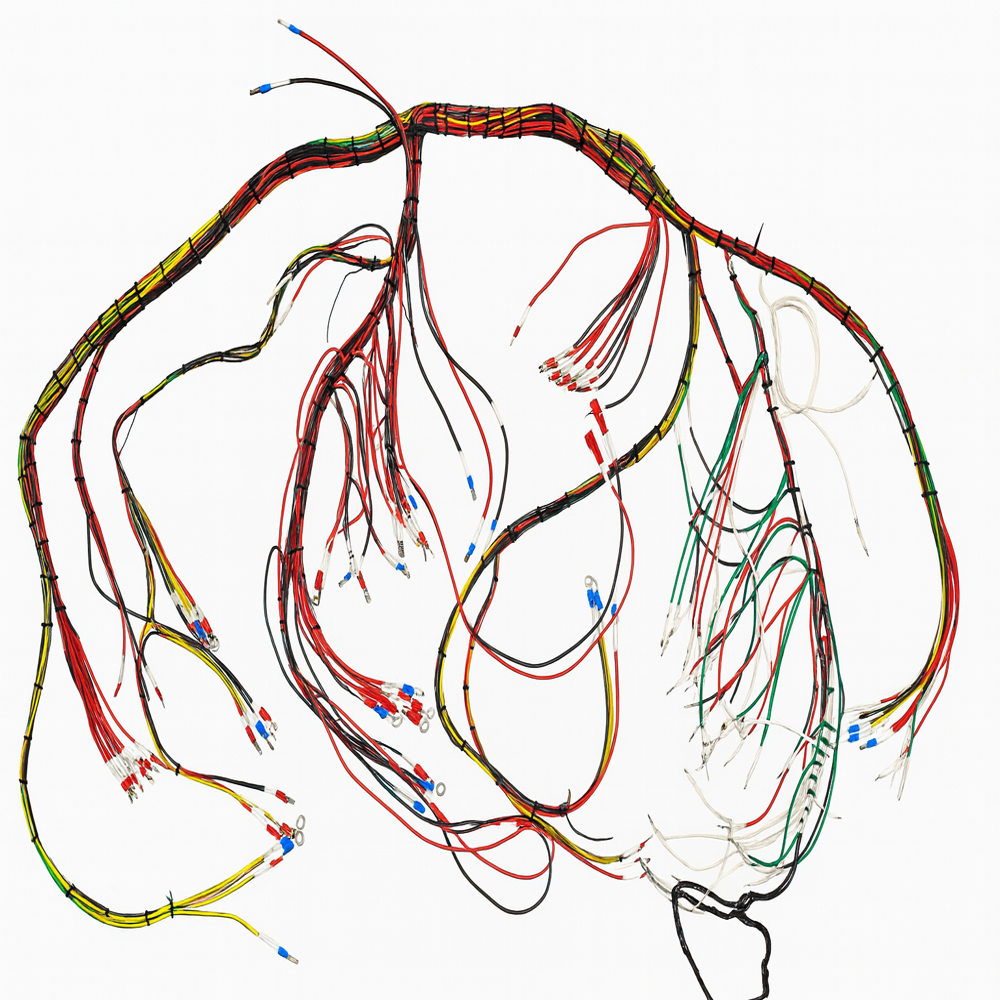

Railway Locomotive Wiring Harness

Price 500 INR/ Piece

Railway Locomotive Wiring Harness Specification

- Product Type

- Railway Locomotive Wiring Harness

- Color

- Black

- Warranty

- 1 Year

- Usage & Applications

- Industrial

- Rated Voltage

- 220 Volt (V)

- Phase

- Single Phase

- Display Type

- No

- Frequency

- 50 Hertz (HZ)

- Features

- Good Quality

- Material

- Plastic

Railway Locomotive Wiring Harness Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 7 Days

About Railway Locomotive Wiring Harness

FAQs of Railway Locomotive Wiring Harness:-

Q1. What is a railway locomotive wiring harness used for?

Q2. Why are special wiring harnesses required for locomotives?

Q3. What materials are used in railway locomotive wiring harnesses?

Q4. Are railway locomotive wiring harnesses compliant with safety standards?

Q5. Can railway locomotive wiring harnesses be customized?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

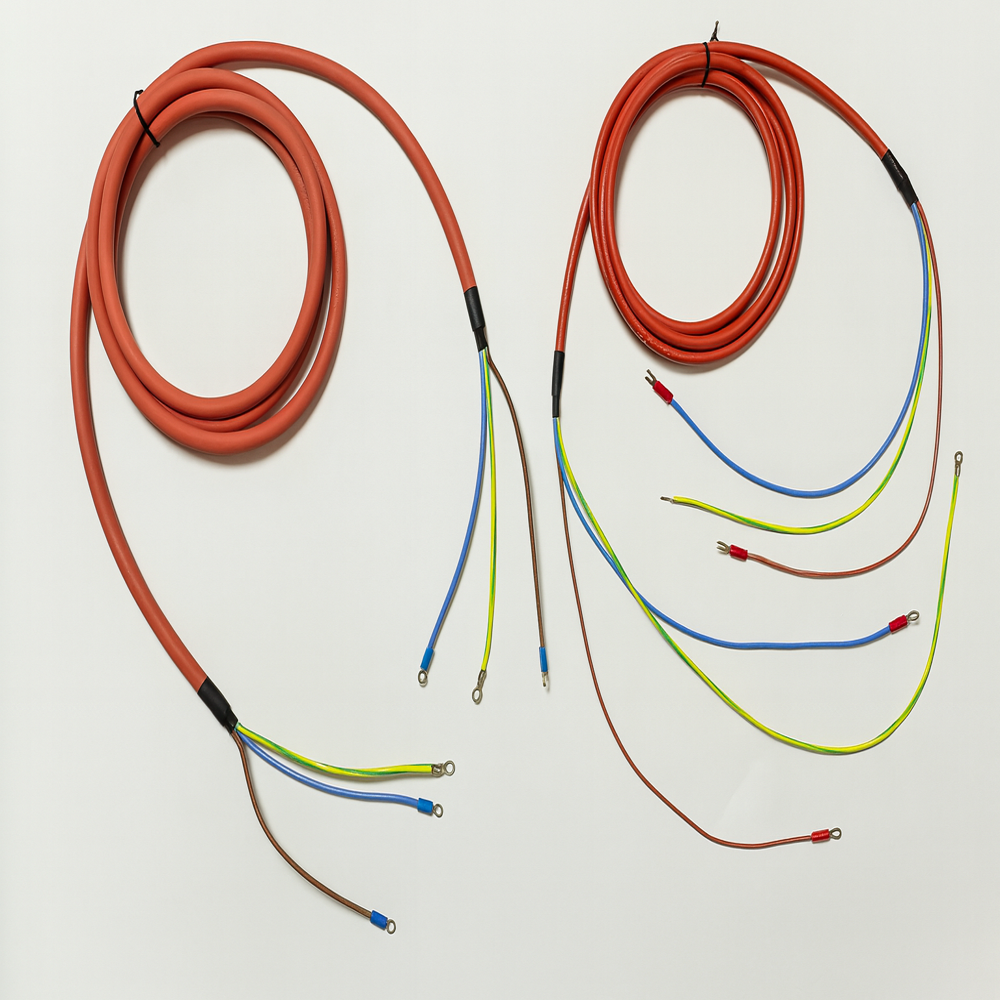

More Products in Wiring Harness Manufacturer Category

Medical Equipment Wiring Harness

Price 2000.0 INR / Number

Minimum Order Quantity : 500

Product Type : Harness

Rated Voltage : 24 Volt (V)

Features : Durable

Application : Electronic

Petrol Pump Dispensers Wiring Harness

Price 1150.0 INR / Number

Minimum Order Quantity : 200

Product Type : Harness

Rated Voltage : 220 Volt (V)

Features : Durable

Wire Harness Assembly

Price 150.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : Wire Harness Assembly

Rated Voltage : 220 Volt (V)

Features : Good Quality

Application : Automobile

Automotive Wiring Harness

Price 150 INR / Piece

Minimum Order Quantity : 500 Pieces

Product Type : Automotive Wiring Harness

Rated Voltage : 12 Volt (V)

Features : Good Quality

Application : Automobile

Send Inquiry

Send Inquiry