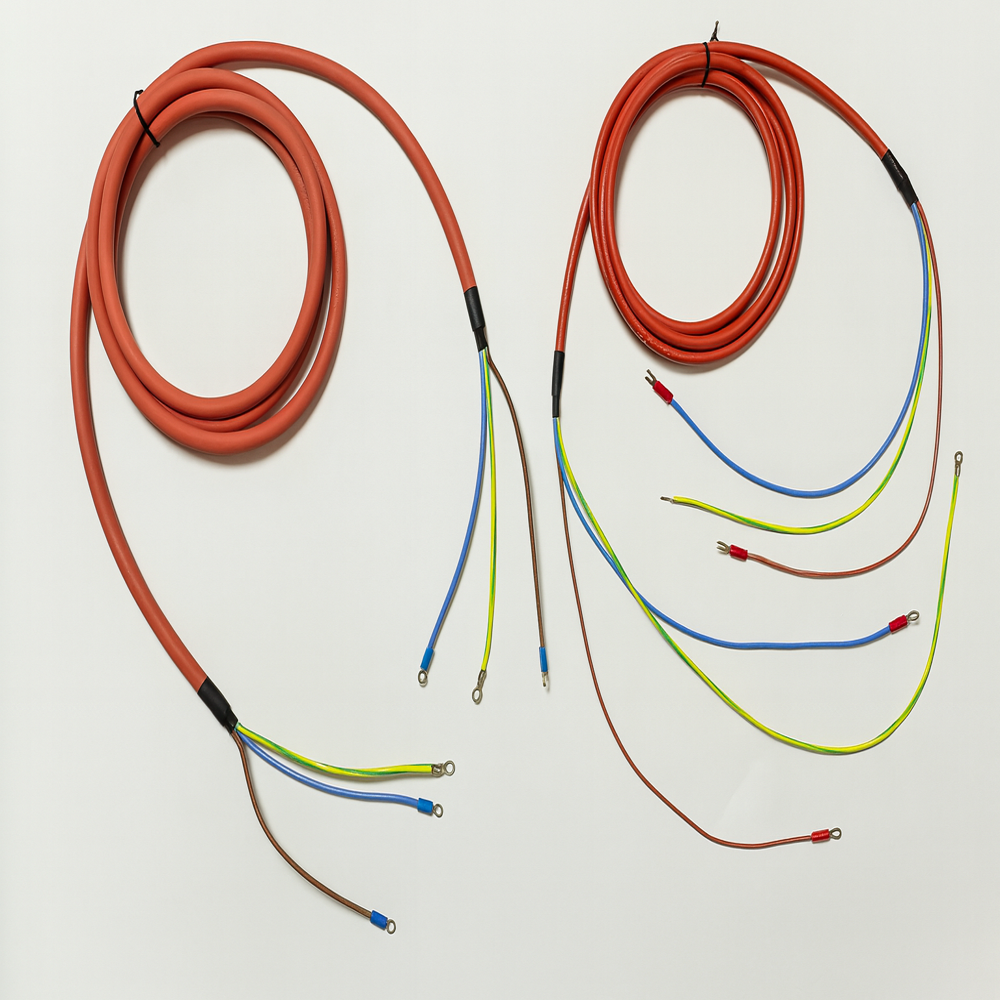

Wire Harness Assembly

Price 150.0 INR/ Piece

Wire Harness Assembly Specification

- Product Type

- Wire Harness Assembly

- Application

- Automobile

- Color

- White

- Warranty

- 1 Year

- Jacket

- PVC

- Rated Voltage

- 220 Volt (V)

- Usage & Applications

- Industrial

- Phase

- Single Phase

- Display Type

- No

- Frequency

- 50 Hertz (HZ)

- Features

- Good Quality

Wire Harness Assembly Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 7 Days

About Wire Harness Assembly

FAQs of Wire Harness Assembly:-

Q1. What is a wire harness assembly used for?

Q2. What materials are used in wire harness assemblies?

Q3. What industries use wire harness assemblies?

Q4. What are the benefits of using a wire harness assembly?

Q5. Can wire harness assemblies be customized?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wiring Harness Manufacturer Category

Petrol Pump Dispensers Wiring Harness

Price 1150.0 INR / Number

Minimum Order Quantity : 200

Rated Voltage : 220 Volt (V)

Product Type : Harness

Phase : Single

Railway Locomotive Wiring Harness

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Rated Voltage : 220 Volt (V)

Product Type : Railway Locomotive Wiring Harness

Phase : Single Phase

Frequency : 50 Hertz (HZ)

Automotive Wiring Harness

Price 150 INR / Piece

Minimum Order Quantity : 500 Pieces

Rated Voltage : 12 Volt (V)

Product Type : Automotive Wiring Harness

Phase : Single Phase

Frequency : 50 Hertz (HZ)

Electronic Energy Meter Wiring Harness

Price 50 INR / Piece

Minimum Order Quantity : 5000 Pieces

Rated Voltage : 220 Volt (V)

Product Type : Electronic Energy Meter Wiring Harness

Phase : Single Phase

Frequency : 50 Hertz (HZ)

Send Inquiry

Send Inquiry